What’s The Technology Features Of Palm Oil Fractionation Plant?

Fatty acids and unsaturated fatty acids in palm oil is 50-50,which giving the palm oil better stability than other oils, it can be used as frying oil palm itself. Rational use of palm oil is to be fractionated palm oil, and make a variety of products. We can provide professional palm oil fractionation plant. Palm oil Fractionation

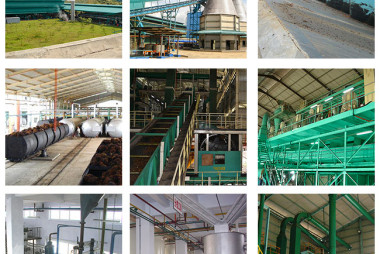

Palm Oil Extraction Plant Design Advantages Introduction

Palm oil extraction plant is palm kernel cake after extraction, mixing oil evaporation, wet meal distilled off, the solvent condensate recovery, tail gas paraffin recycling process to obtain crude oil and meal production workshop. Extraction production plant include the extraction section,wet meal distilled off section, mixed oil evaporation process, the solvent recovery process,tail gas paraffin recycling

READ MORE